Cut Smarter,

Waste Less

- Optimize material usage & reduce waste

- Automate cutting sequences for linear materials

- Maximize efficiency with smart nesting algorithms

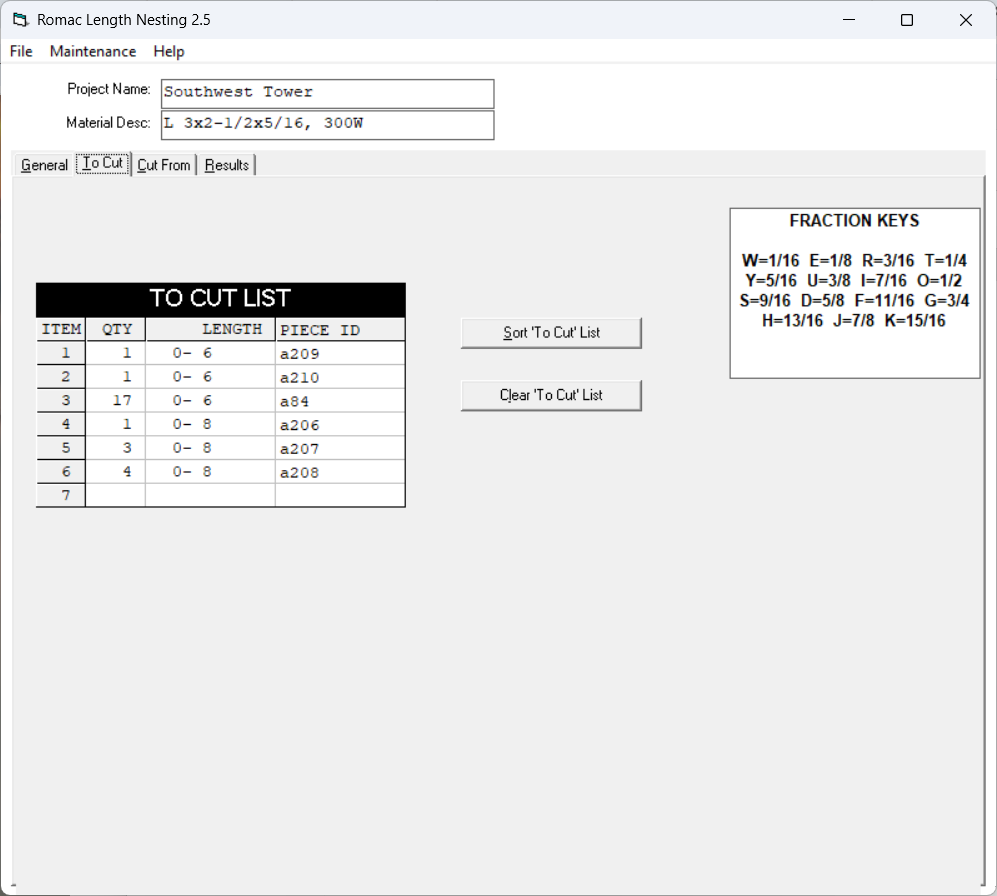

Length Nesting

Fast | Easy | Accurate

Only $100 per year

Designed for steel service centers and fabricators, Length Nesting simplifies the process of determining the most efficient cutting patterns for beams, pipes, bars, and more—saving you time and reducing material costs.

Only $100 PER YEAR

Automate & Optimize

Manually planning cut sequences can lead to excess scrap, wasted material, and lost profits. Length Nesting automates and optimizes cutting sequences, ensuring you get the most out of every piece of stock.

Key Features

✔ Smart Nesting Algorithms – Generate optimized cut patterns for maximum material efficiency

✔ Customizable Cutting Allowance – Account for saw or shear thickness with kerf settings

✔ Large Material Capacity – Manage up to 160 finish lengths and 40 cut-from lengths

✔ Flexible Measurement Inputs – Enter lengths in feet, inches, fractions, decimals, or millimeters

✔ Automated Data Importing – Import bill of material data from major fabrication software

✔ Pre-Entered Cut Lists – Populate ‘Cut From’ lists instantly with saved sizes & quantities

✔ Individual Piece Tracking – Maintain detailed records of all cut pieces

✔ Easy to Learn & Use – No complicated setup, plus free support available

🔘 Subscribe Now for $100/year

Have Questions?

We're Here to Help

We designed Length Nesting to be so intuitive that most users never need to contact support. But if you do, our team is ready to assist.

Seamless Integration with Your Workflow

Import bill of material data effortlessly from leading fabrication software:

Why Choose ROMAC

Reduce Waste, Save Money

With optimized cutting sequences, Length Nesting helps fabricators reduce scrap, saving money on raw materials and increasing efficiency.

How Quickly Can You Get Started?

With a simple setup and intuitive design, you’ll be up and running in just a few hours—no IT team required.

✔ Tekla Structures

✔ SDS/2

✔ Autodesk Advance Steel

✔ P2 Programs & Softscan

✔ Romac Production Control

✔ MS Excel & KISS Format Files

⚡ Eliminate manual data entry and streamline your workflow in seconds.

✔ Minimize excess material waste

✔ Eliminate costly estimation errors

✔ Speed up production with automated cut sequencing

🚀 Be up and running in just minutes!

✔ Simple installation—no IT team required

✔ Import data and start nesting immediately

✔ Free support available (if needed)