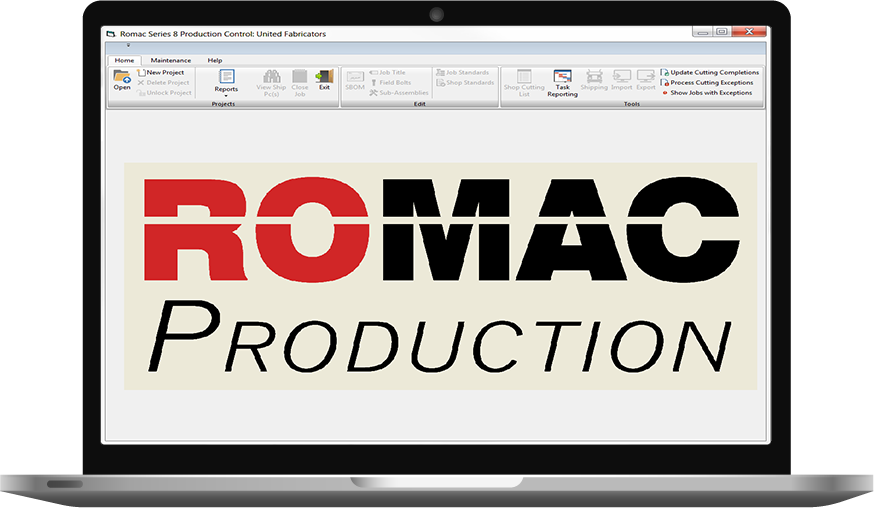

Production Control

Fast | Easy | Accurate

Only $69 per month

- Eliminate manual errors

- Automate production tracking

- Streamline shipping and fabrication

Designed for steel fabricators, Production Control simplifies your workflow—from material tracking to shipping—so you can focus on getting the job done efficiently.

Only $69 per month

Powerful Features to Optimize Your Shop Floor

Production Control is built for small and medium-sized steel fabrication businesses that need an easy-to-use, cost-effective solution for managing production milestones, cutting lists, and shipping.

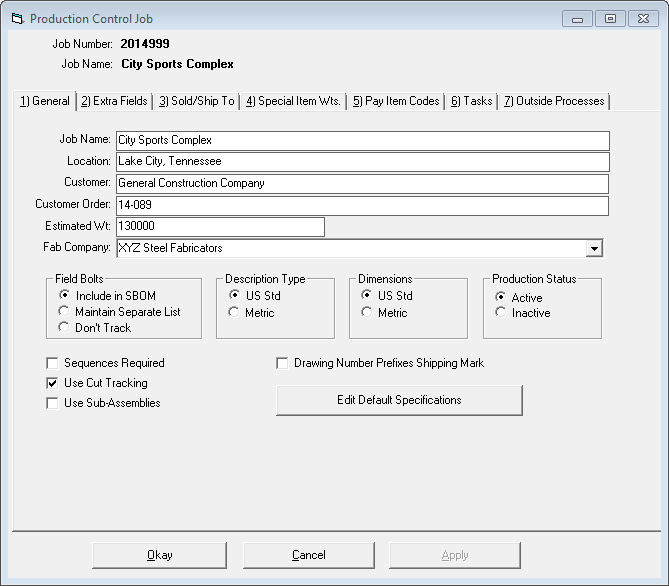

What You Get

- Shop Bill of Material – Organize and manage materials seamlessly

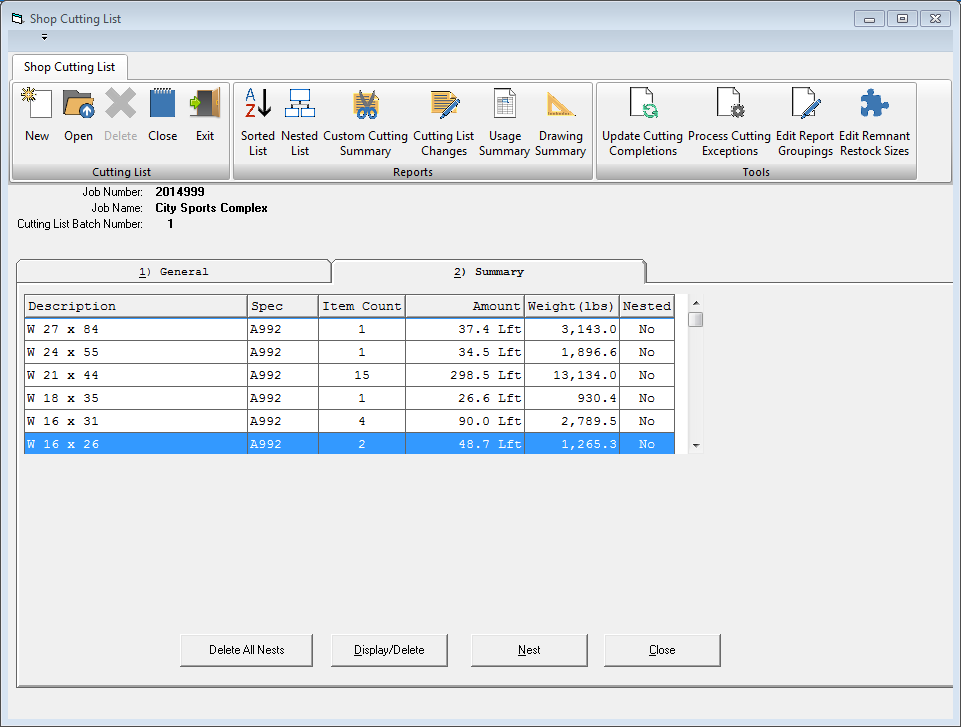

- Shop Cutting Lists – Automatically sort and optimize material cutting

- Production Tracking – Stay on top of milestones from start to finish

- Shipping Tickets – Print and track shipments with ease

- Custom User Database – Tailor your settings to fit your shop's workflow

- Flexible Shop & Job Standards – Configure standards for consistency

- Seamless Integration – Import and export data from leading fabrication software

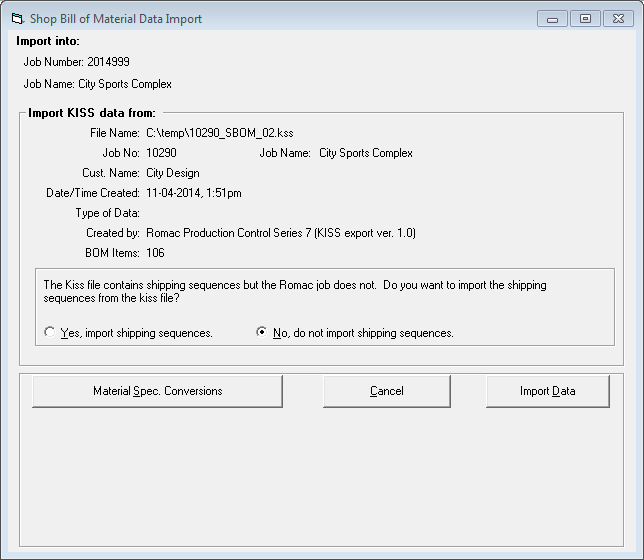

Seamless Integration with Your Existing Workflow

Production Control eliminates manual data entry errors by integrating directly with the industry’s leading software:

- Tekla Structures

- SDS/2

- Autodesk Advance Steel

- P2 Programs

- Softscan

- KISS Flie Compatible (Import & Export)

- Microsoft Excel Export

Save time, reduce errors, and boost efficiency by syncing with the software you already use.

Have Questions?

We're Here to Help

We designed Production Control to be so intuitive that most users never need to contact support. But if you do, our team is ready to assist.

Why Choose ROMAC

While competitors charge thousands per year, Production Control is only $69 per month—making it the best value in steel fabrication production management.

How Quickly Can You Get Started?